The libertarian cries tyranny as he strikes youThe libertarians preach free speech until it's actually something they don't like. Then it's authoritarianism. Seymour is a classic example.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note : This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Politics 🗳️ NZ Politics

- Thread starter wizard of Tauranga

- Start Date

- Thread starter

- #11,383

You missed my whole point questioning if the unique conditions that led to that changed?The last time the "red tape" was cut - the cost of which has affected millions of lives and is still ongoing

The 'Rottenomics' of the $47 billion leaky homes market failure

Stuff

www.stuff.co.nz

And back then we had council inspections and consenting which did zero…

A few comments:

1 - don’t we have qualifications and registration for builders now so they can’t fold a company, walk away and restart again as easily, which wasn’t the case during peak leaky building? Do you think this will have an effect?

No, the Licensed Builder scheme doesn’t prevent people closing one company and starting another. A LBP can be fined and even have their license removed for not meeting the standards set by the board but changing their company isn’t one of them. They can also just leave their company and, while unlicensed, go and work for another builder who “supervisors” their mistakes, sorry, work.

While it’s still possible now to change materials, if the designer is prepared to endorse the change, back then it was common place. We’d specify Harditex Premier but the builder would find Etherpan was on sale and swap to that.2 - most houses are designed by architects/ designers with the builders just using what’s the highly qualified architect/ designer specifies. The leaky building issues were mainly due to monolithic cladding, lack of eaves, untreated timber, etc (all designer specified - not builders). Councils were involved then and it still happened. I kind of feel it was all systemic and nothing could have been done to averted it as experienced, knowledgeable, independent and highly qualified people oversaw it all happen. A sharp industry wide learning curve. With these issues now known, are we building better? Are engineers, architects and a lot more highly qualified builders enough safeguards?

No matter how many times I’d show where control joints in claddings were supposed to be, either the client would think they were ugly (especially when no other houses in the street had them) or the builder just couldn’t be bothered putting them in. Auckland can have four seasons in one day. You have a hot day and then there’s a thunder storm. The paint, plaster, mesh, cement board and timber frame all have different thermal co-efficients so they’ve heated up but when that rain hits them, everything cools at a different rate and when one moves to much faster or slower than another component of the cladding/wall, cracks will occur if not controlled properly.

In most plaster finished houses with plaster over a cement board, the only thing that’s stopping water entering, is the paint which should be repainted every.8-10 years to maintain watertightness which is then a maintenance issue, not a construction issue. That’s why manufacturers insist they be repainted and why watertightness claims can only go back 10 years.

I’ve always shown that a pergola should be supported at the wall on a ribbon plate with a flashing over it. But, how many times have you seen pergola rafters disappearing under a cladding and into a wall without even saddle flashings over them.

Where a roof is sloping down beside a wall, there is supposed to be a diverter flashing behind the cladding at the gutter. I’ve seen the owner of a house next to ours cutting them out. When I said they needed to be there for waterproofing, he just insisted on removing them because “they were ugly”. Three years latter, he was recladding the house.

Untreated timber was brought in because the National government in the Nineties only listened to the timber industry who didn’t like the cost and the Greens were concerned about CCA timber treatment…. the “A” being arsenic. They were concerned that people could be exposed to it (unlikely because it became inert when combined with the other chemicals) and waste material contaminating waterways.

Now, we’re required to provide details for every roof and wall cladding when, back then, we would only be required to provide sections through the building. Leaky homes was also brought about because builders didn’t know what they were doing but Seymour thinks insuring them would make them competent? Without plans needing to be checked, unless the insurer insisted on it, designers will go back to producing lightweight documents as they’d only need to spend 1/4 of the time producing drawings to the standard before the building act.

And yes, some designers were definitely stupid with their designs…. NZ is a sub-tropical country with a high rainfall…. it’s not suited to certain architectural styles or relying on sealants over mechanical flashings.

3 - I feel with less compliance, and less double and sometimes triple checking, I could see house build costs dropping maybe 20%? With those sort of savings and a more highly skilled and knowledgeable workforce, a small amount of shoddy work is more than compensated by overall costs savings, benefits to first home buyers, reduction in homelessness and all the social issues driven from lower property ownership.

The problem isn’t with the cost of inspection but in the time spent processing applications. Even with in a group of Building Officers from the same council, they disagree on what’s required. Since most councils now only accept applications electronically these days, I’d prefer an extended MBIE to process all applications centrally (or at least based in the four main centres) and council’s still handle inspections locally.

Our double gold plating of housing is costing to much in negative social issues.

BTW, I always specified treated timber even when it wasn’t required. I’ve had two leaky buildings over the last 35 years plus of producing documentation. One, the builder left out the flashings over the windows.

The second, the Builder illegally changed from the detailed and specified product to an inferior one. He also put overflows to solid balustrades above the floor level, fell decks away from sumps, and, in one place, didn’t even provide the downpipe within a column for the deck sump. That project was overseen by a private building inspector who lost his license over that project. Last I heard, he was a head compliance officer in Auckland Council’s watertightness department…. heaven help anyone’s project he’s consenting or inspecting. The builder changed the name of his company in order to avoid paying too repair the project or contribute to the repairs.

- Thread starter

- #11,386

Random though, should the designer sign off the building rather than council?No, the Licensed Builder scheme doesn’t prevent people closing one company and starting another. A LBP can be fined and even have their license removed for not meeting the standards set by the board but changing their company isn’t one of them. They can also just leave their company and, while unlicensed, go and work for another builder who “supervisors” their mistakes, sorry, work.

While it’s still possible now to change materials, if the designer is prepared to endorse the change, back then it was common place. We’d specify Harditex Premier but the builder would find Etherpan was on sale and swap to that.

No matter how many times I’d show where control joints in claddings were supposed to be, either the client would think they were ugly (especially when no other houses in the street had them) or the builder just couldn’t be bothered putting them in. Auckland can have four seasons in one day. You have a hot day and then there’s a thunder storm. The paint, plaster, mesh, cement board and timber frame all have different thermal co-efficients so they’ve heated up but when that rain hits them, everything cools at a different rate and when one moves to much faster or slower than another component of the cladding/wall, cracks will occur if not controlled properly.

In most plaster finished houses with plaster over a cement board, the only thing that’s stopping water entering, is the paint which should be repainted every.8-10 years to maintain watertightness which is then a maintenance issue, not a construction issue. That’s why manufacturers insist they be repainted and why watertightness claims can only go back 10 years.

I’ve always shown that a pergola should be supported at the wall on a ribbon plate with a flashing over it. But, how many times have you seen pergola rafters disappearing under a cladding and into a wall without even saddle flashings over them.

Where a roof is sloping down beside a wall, there is supposed to be a diverter flashing behind the cladding at the gutter. I’ve seen the owner of a house next to ours cutting them out. When I said they needed to be there for waterproofing, he just insisted on removing them because “they were ugly”. Three years latter, he was recladding the house.

Untreated timber was brought in because the National government in the Nineties only listened to the timber industry who didn’t like the cost and the Greens were concerned about CCA timber treatment…. the “A” being arsenic. They were concerned that people could be exposed to it (unlikely because it became inert when combined with the other chemicals) and waste material contaminating waterways.

Now, we’re required to provide details for every roof and wall cladding when, back then, we would only be required to provide sections through the building. Leaky homes was also brought about because builders didn’t know what they were doing but Seymour thinks insuring them would make them competent? Without plans needing to be checked, unless the insurer insisted on it, designers will go back to producing lightweight documents as they’d only need to spend 1/4 of the time producing drawings to the standard before the building act.

And yes, some designers were definitely stupid with their designs…. NZ is a sub-tropical country with a high rainfall…. it’s not suited to certain architectural styles or relying on sealants over mechanical flashings.

The problem isn’t with the cost of inspection but in the time spent processing applications. Even with in a group of Building Officers from the same council, they disagree on what’s required. Since most councils now only accept applications electronically these days, I’d prefer an extended MBIE to process all applications centrally (or at least based in the four main centres) and council’s still handle inspections locally.

BTW, I always specified treated timber even when it wasn’t required. I’ve had two leaky buildings over the last 35 years plus of producing documentation. One, the builder left out the flashings over the windows.

The second, the Builder illegally changed from the detailed and specified product to an inferior one. He also put overflows to solid balustrades above the floor level, fell decks away from sumps, and, in one place, didn’t even provide the downpipe within a column for the deck sump. That project was overseen by a private building inspector who lost his license over that project. Last I heard, he was a head compliance officer in Auckland Council’s watertightness department…. heaven help anyone’s project he’s consenting or inspecting. The builder changed the name of his company in order to avoid paying too repair the project or contribute to the repairs.

Someone qualified that understands the systems rather than council incompetents that don’t have a clue and spend forever in time and cost trying to sign off something they don’t fully understand.

I mean if they miss flashings… their inspections are pointless! I think most of the council hassle and cost is because they don’t have the expertise to do their job. They need layers of check and balances to cross every i and dot every t (deliberately wrong way around to show how incompetent they are) which just frustrates everyone… then they still miss things!

Ps I think it’s more developers who are the potential problem rather than builders.

Last edited:

- Thread starter

- #11,387

On the LBP, yes they can fold a company but they are still personally held accountable for dodgy work in regards to licensing? No use starting another company if you lost your ability to build?No, the Licensed Builder scheme doesn’t prevent people closing one company and starting another. A LBP can be fined and even have their license removed for not meeting the standards set by the board but changing their company isn’t one of them. They can also just leave their company and, while unlicensed, go and work for another builder who “supervisors” their mistakes, sorry, work.

While it’s still possible now to change materials, if the designer is prepared to endorse the change, back then it was common place. We’d specify Harditex Premier but the builder would find Etherpan was on sale and swap to that.

No matter how many times I’d show where control joints in claddings were supposed to be, either the client would think they were ugly (especially when no other houses in the street had them) or the builder just couldn’t be bothered putting them in. Auckland can have four seasons in one day. You have a hot day and then there’s a thunder storm. The paint, plaster, mesh, cement board and timber frame all have different thermal co-efficients so they’ve heated up but when that rain hits them, everything cools at a different rate and when one moves to much faster or slower than another component of the cladding/wall, cracks will occur if not controlled properly.

In most plaster finished houses with plaster over a cement board, the only thing that’s stopping water entering, is the paint which should be repainted every.8-10 years to maintain watertightness which is then a maintenance issue, not a construction issue. That’s why manufacturers insist they be repainted and why watertightness claims can only go back 10 years.

I’ve always shown that a pergola should be supported at the wall on a ribbon plate with a flashing over it. But, how many times have you seen pergola rafters disappearing under a cladding and into a wall without even saddle flashings over them.

Where a roof is sloping down beside a wall, there is supposed to be a diverter flashing behind the cladding at the gutter. I’ve seen the owner of a house next to ours cutting them out. When I said they needed to be there for waterproofing, he just insisted on removing them because “they were ugly”. Three years latter, he was recladding the house.

Untreated timber was brought in because the National government in the Nineties only listened to the timber industry who didn’t like the cost and the Greens were concerned about CCA timber treatment…. the “A” being arsenic. They were concerned that people could be exposed to it (unlikely because it became inert when combined with the other chemicals) and waste material contaminating waterways.

Now, we’re required to provide details for every roof and wall cladding when, back then, we would only be required to provide sections through the building. Leaky homes was also brought about because builders didn’t know what they were doing but Seymour thinks insuring them would make them competent? Without plans needing to be checked, unless the insurer insisted on it, designers will go back to producing lightweight documents as they’d only need to spend 1/4 of the time producing drawings to the standard before the building act.

And yes, some designers were definitely stupid with their designs…. NZ is a sub-tropical country with a high rainfall…. it’s not suited to certain architectural styles or relying on sealants over mechanical flashings.

The problem isn’t with the cost of inspection but in the time spent processing applications. Even with in a group of Building Officers from the same council, they disagree on what’s required. Since most councils now only accept applications electronically these days, I’d prefer an extended MBIE to process all applications centrally (or at least based in the four main centres) and council’s still handle inspections locally.

BTW, I always specified treated timber even when it wasn’t required. I’ve had two leaky buildings over the last 35 years plus of producing documentation. One, the builder left out the flashings over the windows.

The second, the Builder illegally changed from the detailed and specified product to an inferior one. He also put overflows to solid balustrades above the floor level, fell decks away from sumps, and, in one place, didn’t even provide the downpipe within a column for the deck sump. That project was overseen by a private building inspector who lost his license over that project. Last I heard, he was a head compliance officer in Auckland Council’s watertightness department…. heaven help anyone’s project he’s consenting or inspecting. The builder changed the name of his company in order to avoid paying to repair the project or contribute to the repairs.

Ultimately they can avoid the financial impact but they get banned and can’t repeat it? That in itself should serve as a driver to keep to the rules in the first place?

It’s my experience that LBP’s value their license and are now more professional.

And yes, they can just work for someone else, but that LBP is accountable and loses his license if he doesn’t oversee the guy?

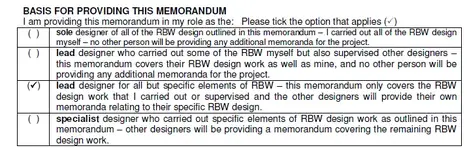

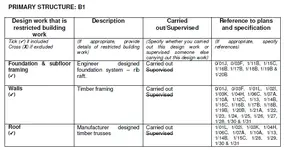

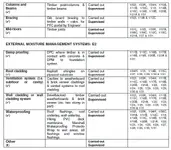

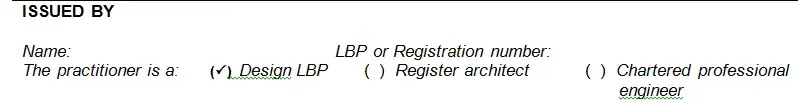

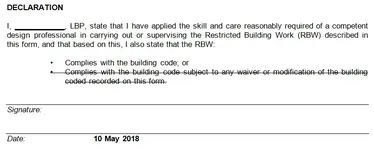

I already do have to sign off on them and provide the council with this:Random though, should the designer sign off the building rather than council?

Someone qualified that understands the systems rather than council incompetents that don’t have a clue and spend forever in time and cost trying to sign off something they don’t fully understand.

I mean if they miss flashings… their inspections are pointless! I think most of the council hassle and cost is because they don’t have the expertise to do their job. They need layers of check and balances to cross every i and dot every t (deliberately wrong way around to show how incompetent they are) which just frustrates everyone… then they still miss things!

Ps I think it’s more developers who are the potential problem rather than builders.

Form 2A

Memorandum from Licensed Building Practitioner: Certificate of Design Work

Section 45 and Section 30C, Building Act 2004

I have to identify myself as being licensed to undertake restricted building work and to provide information for all the structural elements, wall and roof claddings, foundations including any drawings (along with amendment numbers).

Anytime Council ask for amendments to drawings, I've also got to alter the CoDW for any of the drawings changed and include the new amendment ID. Where builders/owners get into trouble is when they change say the roof cladding from one manufacturer to another. Before the CCC is issued, Council requires designers to alter the Certificate of Design Work (CoDW) and drawings to suit the new system. But if the designer thinks that the product which has been used is inferior to the one specified, they can refuse to alter the drawings and refuse to reissue the CoDW meaning the client/builder won't be issued a CCC as Council want "someone else to blame" (i.e. the designer) if it goes pear shaped because the designer has said that they "have applied the skill and care reasonably required .... blah, blah, blah."

Basically, the whole of the construction has become a butt covering industry with "all care and no responsibility" (especially when that responsibility can be passed on to someone else).

Since April of this year, a total of three LBP's have been suspended.... two for bad building practices and one for altering the date on a certificate of title. With over 27,000 LBP's in NZ, that's a pretty small percentage. Basically, you've got to be the worst of the worst to get suspended.... you're more likely to get fined and/or sent for further training.On the LBP, yes they can fold a company but they are still personally held accountable for dodgy work in regards to licensing? No use starting another company if you lost your ability to build?

Ultimately they can avoid the financial impact but they get banned and can’t repeat it? That in itself should serve as a driver to keep to the rules in the first place?

It’s my experience that LBP’s value their license and are now more professional.

And yes, they can just work for someone else, but that LBP is accountable and loses his license if he doesn’t oversee the guy?

There's another issue with the sale of this apartment. If it had occurred in February, he would have been caught out by the Brightline test and would have had to pay over $70,000 in tax on the capital gain from when he brought it. But, the government reduced the Brightline test back to two years.... so he's avoided paying it. Corruption!!!It was more the fact he was crying about wasteful government spending & yet smashing every "entitlement he's entitled to".

Every country has a PM or Prime Ministers residence with up keep.

But does every country have a PM who has a freehold apartment that the tax payer ends up paying for him to live in.

100%There's another issue with the sale of this apartment. If it had occurred in February, he would have been caught out by the Brightline test and would have had to pay over $70,000 in tax on the capital gain from when he brought it. But, the government reduced the Brightline test back to two years.... so he's avoided paying it. Corruption!!!

Appreciate the building insights

As gordon campbell eloquently puts, neoliberalism is manifest yet again

thedig.nz

thedig.nz

Gordon Campbell on the Dunedin hospital fiasco - The Dig

The word “blow-out” is such a politically loaded term. It carries a strong whiff of extravagance and incompetence. In fact, and with public health budgets in particular, going “over budget”…View Story

Another radical commie leftie preaching for the capital gains tax

www.newstalkzb.co.nz

www.newstalkzb.co.nz

Kerre Woodham: Just introduce a capital gains tax and be done with it

Kerre Woodham thinks Chris Hipkins has lost his credibility when it comes to capital gains taxes, but thinks we should just introduce one and get it over w

Our pm enjoys his spoils

www.1news.co.nz

www.1news.co.nz

Revealed: Luxon set to gain almost $500k on property sales

Labour says it means the Prime Minister is in a "conflicted position" and should be open to discussing capital gains tax.

I'm wondering what he knows & to suddenly been selling a bit of his property portfolio all of a sudden.There's another issue with the sale of this apartment. If it had occurred in February, he would have been caught out by the Brightline test and would have had to pay over $70,000 in tax on the capital gain from when he brought it. But, the government reduced the Brightline test back to two years.... so he's avoided paying it. Corruption!!!

Probably going to invest in a private hospital down south, the oil industry, BA Tobacco and Gun City.

Terrible writing.As gordon campbell eloquently puts, neoliberalism is manifest yet again

Gordon Campbell on the Dunedin hospital fiasco - The Dig

The word “blow-out” is such a politically loaded term. It carries a strong whiff of extravagance and incompetence. In fact, and with public health budgets in particular, going “over budget”…View Storythedig.nz

$26,000 per Dunedin resident. Absolute madness. Adelaide's debacle was only $1,800 per resident.

- Thread starter

- #11,397

And: ‘the construction costs have risen from $10,000 per square metre at the project outset to $30,000 per square metre today.’Terrible writing.

$26,000 per Dunedin resident. Absolute madness. Adelaide's debacle was only $1,800 per resident.

That’s just through the roof! A house is what, $3k pm; a bespoke custom made mansion $6k?

I understand hospitals have specialist stuff but at $30k per m, questions need to be asked.

Is that for the 120K metro Dunedin pop or the entire lower SI?$26,000 per Dunedin resident. Absolute madness. Adelaide's debacle was only $1,800 per reresident.

Your work stories are terrifying MikeI already do have to sign off on them and provide the council with this:

Form 2A

Memorandum from Licensed Building Practitioner: Certificate of Design Work

Section 45 and Section 30C, Building Act 2004

View attachment 9741

I have to identify myself as being licensed to undertake restricted building work and to provide information for all the structural elements, wall and roof claddings, foundations including any drawings (along with amendment numbers).

View attachment 9743

View attachment 9744

View attachment 9745

View attachment 9746

Anytime Council ask for amendments to drawings, I've also got to alter the CoDW for any of the drawings changed and include the new amendment ID. Where builders/owners get into trouble is when they change say the roof cladding from one manufacturer to another. Before the CCC is issued, Council requires designers to alter the Certificate of Design Work (CoDW) and drawings to suit the new system. But if the designer thinks that the product which has been used is inferior to the one specified, they can refuse to alter the drawings and refuse to reissue the CoDW meaning the client/builder won't be issued a CCC as Council want "someone else to blame" (i.e. the designer) if it goes pear shaped because the designer has said that they "have applied the skill and care reasonably required .... blah, blah, blah."

Basically, the whole of the construction has become a butt covering industry with "all care and no responsibility" (especially when that responsibility can be passed on to someone else).

What's the connection between Trump and Key resigning?Stuff

www.stuff.co.nz

Interesting to see John Key would be keen to see a trump win. Always thought it was weird how key stepped down right as trump was announced president in 2016 and at the height of his popularity. Ardern too stepped away later on as key did

Similar threads

Current Affairs

🗳️ Is this the twilight of democracy?

- Replies

- 160

- Views

- 32K

- Replies

- 3

- Views

- 3K